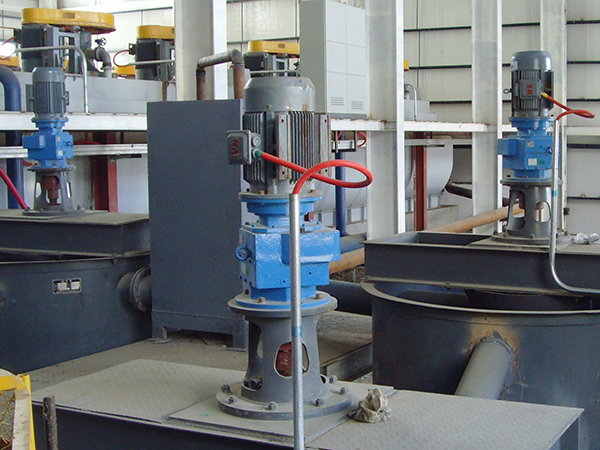

Working Principle

The material (pulp) enters the conical rotary cylinder from the upper side of the tank and mixes with the agent added from the top of the tank, and then enters the center of the tank. After mixing, the material (pulp) is discharged from the upper overflow weir, which can prevent the material from "short circuit" and make the agent better effects on the mineral particles.

Features

Compared with the other type of agitation tank, the main technical features of our high-efficiency agitation tank are as follows:

(1) High efficiency. The unique flow track design makes the slurry circulate up and down according to the W-shaped, and the solid particles in the slurry are fully dispersed. With the unique reagent adding device, the reagent can be evenly and fully dispersed in the pulp to speed up the effect of the reagent and reduce the consumption of the reagent.

(2) Low energy consumption. The mixing tank optimizes the design of the new structure of sleeve body with low energy consumption distribution, impeller, guide plate and baffle, compared with the other type of mixing tank, the power consumption per unit volume is reduced by 1/4 -- 1/3.

(3) Low wear. It can effectively prolong the overall equipment’s service life. Under the same impeller material, the life of the impeller can be increased by more than 6 times. If lined with wear-resistant rubber, it can be increased by more than 10 times.

(4) High strength, non-sinking, high suspension degree of pulp, especially suitable for the slurry of high density ore mixing.

(5) Easy maintenance. The parts are easy to disassemble and repair.

(6) Famous brand reducer can ensure the service life of shaft and bearing.

Parameters

|

Models |

Specifications |

Effective volume |

Diameter of impeller |

Revolution of impeller |

Driving motor |

Weight |

|

|

Models |

Power |

||||||

|

|

mm |

m3 |

mm |

r/min |

|

kW |

t |

|

ZGJ-1000 |

Φ1000×1000 |

0.58 |

240 |

530 |

Y90L-6 |

1.1 |

0.685 |

|

ZGJ-1500 |

Φ1500×1500 |

2.2 |

400 |

320 |

Y132S-6 |

3 |

1.108 |

|

ZGJ-2000 |

Φ2000×2000 |

5.46 |

550 |

230 |

Y132M2-6 |

5.5 |

1.5 |

|

ZGJ-2500 |

Φ2500×2500 |

11.2 |

650 |

280 |

Y200L-6 |

18.5 |

3.46 |

|

ZGJ-3000 |

Φ3000×3000 |

19.1 |

700 |

210 |

Y225S-8 |

18.5 |

5.19 |

|

ZGJ-3500 |

Φ3500×3500 |

30 |

850 |

230 |

Y225M-8 |

22 |

6.86 |

|

ZGJ-4000 |

Φ4000×4000 |

45 |

1000 |

210 |

Y280S-8 |

37 |

12.51 |

FAQ

1.What are your prices?

Our prices are subject to model.

2.Can you supply the relevant documentation?

Yes, we can provide most documentation including Certificates of Analysis / Conformance; Insurance; Origin, and other export documents where required.

3.What is the average lead time?

The average lead time would be 3 months after advance payment.

4.What kinds of payment methods do you accept?

Negotiable.